The Complete Guide to Exterior Wood Stain: Making Your Outdoor Structures Last Decades

After four decades of building garden structures and tearing out failed decks built by others, we’ve learned what the textbooks don’t teach. Most advice you’ll find online scratches the surface—literally. What follows isn’t theory; it’s what we’ve discovered through thousands of projects, countless failures, and the kind of hard-won wisdom that only comes from getting your hands dirty.

Why Most Outdoor Wood Projects Fail Early

Walk through any neighborhood and you’ll see it: peeling stain, rotting posts, structures that looked beautiful for two years and terrible by year five. The homeowner blames the stain. The builder blames the weather. But the real culprit? Nobody understood the wood itself.

The Species That Will Break Your Heart

Some woods simply won’t survive outdoors, no matter what you do. We’ve seen builders use poplar, red oak, balsa, willow, and basswood in exterior projects—even pressure-treated versions. Save yourself the heartache: don’t even try. These species will disappoint you, guaranteed.

Similarly, avoid heat-treated (thermally modified) hardwoods for structural applications. The cooking process that boils off the sap makes many species prone to rot. Worse, manufacturers often use adhesives like polyurethane glue to make up posts, and these joints simply don’t hold up outdoors. We’ve seen posts literally fall apart.

Understanding Wood: The Plant That Became Your Deck

Here’s what changed everything for us: we stopped thinking of lumber as “building material” and started thinking of it as what it really is—sliced-up plant stems.

Consider a 150-foot redwood tree drawing moisture and nutrients from its roots all the way up to its branches. When you cut that tree into lumber, you’re left with what are essentially bundles of microscopic straws. Look at a cut post under your phone’s magnifying glass and you’ll see those pore structures clearly. They wick moisture in through the ends just like they did when the tree was alive.

This is the game-changer: Sealing those end cuts can drastically extend the useful lifetime of wood used outdoors. The larger the tree species, the longer those cellular “straws,” and the more aggressively they’ll pull moisture into your lumber.

The Prefabrication Advantage

If you’re staining any garden structure, consider prefabricating components and pre-staining all six sides before assembly. This approach gives you access to surfaces you’ll never easily reach again and ensures complete protection from the start. It’s extra work upfront that pays dividends for years.

With the right building knowledge and proper maintenance—recoating stain every few years—you can push the lifespan of outdoor structures to 30-50 years. But it starts with understanding what you’re working with.

Why Stain Peels: The Problems Nobody Talks About

Problem 1: The End Grain Trap

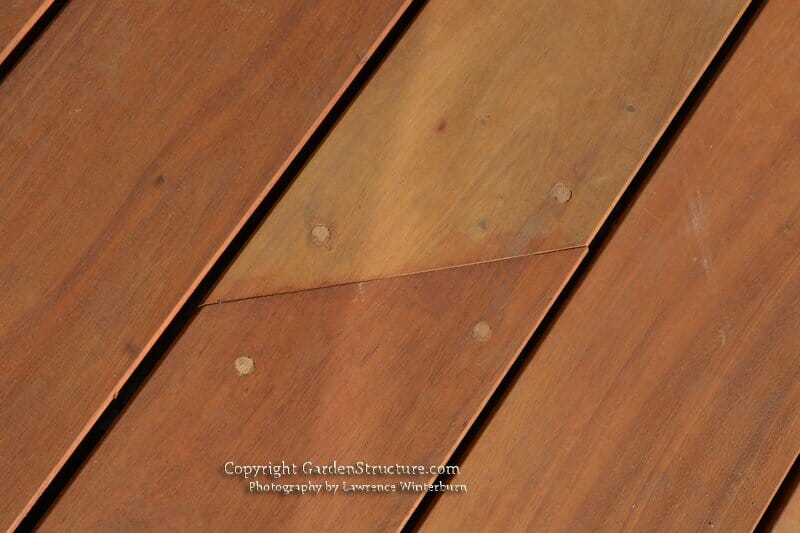

As wood dehydrates, it shrinks. Leave a tree whole after cutting and it will crack toward the center—larger splits at the outer rings, smaller at the core. Fence posts crack on all four sides because the tree’s core creates the shortest path for those cracks to reach each surface.

Solution: Seal the end grains religiously. Every end cut, every time. If you cut a piece during assembly, seal that fresh end before moving on.

Problem 2: Mill Glaze—The Invisible Barrier

During the planing process, superheated sap and sawdust get forced into the wood’s surface, creating what we call “mill glaze.” It’s nearly as dense as glass. You can see it by looking at lumber from an angle under light—that shiny, glazed surface.

Stain will not penetrate mill glaze. It can’t. The pores are sealed shut.

Solution: Sand all surfaces with 80-grit sandpaper on a random orbital sander before staining. This scuffing removes the glaze and opens the pores, giving the stain something to connect to mechanically. Red cedar lumber is particularly prone to mill glaze, and skipping this step is the number one cause of peeling stain we’ve observed.

When sanding, use a respirator and a 3-millimeter shop vacuum. Dust from red cedar and pressure-treated lumber is toxic—take it seriously.

Problem 3: Water-Logged Wood

If the pores of your wood are full of water, stain cannot bond properly. Period.

Solution: If it has rained in the past two weeks, delay stain application. Yes, two weeks. The surface might feel dry, but those deep pores hold moisture much longer than you’d think.

For best results, stack your lumber with 1-2 inch spacers between layers, boards spaced 1 inch apart. Set up fans in your garage and crack the door open a few inches. Dry cedar for two weeks minimum, pressure-treated for three to four weeks. This won’t achieve kiln-dried moisture levels (around 5-8% versus the typical 18-22% moisture content in standard lumber), but it dries the outer surface enough for proper stain penetration.

Most stain manufacturers recommend 15% moisture content or less. Invest in a moisture meter—they’re inexpensive and eliminate guesswork.

The Right Stain for the Job

We prefer oil-based finishes. In our experience, they simply last longer than water-based alternatives.

For tropical hardwoods, we typically use Messmers Oil Finish. For cedar, our go-to products are Superdeck or Cutek. These have proven themselves over years of Ontario winters and summers.

What About Pressure-Treated Lumber?

Here’s an uncomfortable truth: staining pressure-treated lumber will give you limited results. The chemical treatment process fills the wood’s pores with preservatives—essentially a stain-like sealer. Most topical stains won’t bond well because there’s nowhere for them to penetrate. You’d need to sand off the treatment to achieve good adhesion, which defeats the entire purpose of using pressure-treated wood.

There are products specifically formulated for pressure-treated lumber, but frankly, most of our customers use cedar, exotic hardwoods, or PVC for structures where appearance matters.

The Application Process That Actually Works

Preparation Is Everything

- Clean the wood thoroughly to remove dirt, grease, or mildew

- Allow it to dry completely (remember the two-week rule after rain)

- Sand all surfaces with 80-grit paper to remove mill glaze

- Check moisture content with a meter if possible

- Seal all end cuts with a quality end-grain sealer

Application Technique

Apply two thin coats rather than one heavy coat. You can use a brush, roller, or paint pad, but here’s the key: work along the entire length of a board at a time to avoid lap marks or uneven appearance.

Back-brushing is critical. If you use a roller to lay stain on quickly (and rollers are efficient), you must follow up immediately with a brush to work the finish into the pores. Rollers lay stain on the surface; brushes push it where it needs to go.

Stir thoroughly before and during application. Stain settles, and you need uniform consistency and color throughout the job.

The Sunny Day Problem Most People Don’t Know About

Here’s something that caught us by surprise years ago: staining on a sunny day can ruin your results, and most people have no idea why.

Stain manufacturers carefully warm all the component chemicals, mix them together, then cool the mixture while stirring. This process creates a stable emulsion—the finished stain product. But when you apply stain in direct sunlight, the sun heats the wet stain on the wood surface. This heat can break down the emulsion, separating it back into its individual ingredient chemicals. You’re no longer applying stain—you’re applying a breakdown of incompatible components.

Solution: If it’s sunny, work under a tent or canopy to shade your work area, or postpone the job for an overcast day. This single change can mean the difference between stain that lasts seven years and stain that fails in two.

Choosing Your Finish Type

Your options range from clear sealers to semi-transparent stains to solid color stains. Each offers different aesthetics and protection levels.

Clear sealers show off the natural wood grain beautifully but won’t last as long as pigmented products. UV rays are relentless, and pigment is your primary defense against sun damage.

Semi-transparent stains offer a middle ground—you get some color and UV protection while still seeing wood grain and character.

Solid stains provide the most protection and longevity, essentially functioning like thin paint. They last longer than semi-transparent options in general terms, though they do eventually deteriorate, especially on horizontal surfaces that take the full brunt of weather.

The Vertical Versus Horizontal Reality

Vertical surfaces are far easier to protect than horizontal ones. Rain runs off vertical boards; it puddles on horizontal surfaces. Snow slides off railings; it sits on deck floors. UV exposure is more consistent and severe on flat surfaces.

This is why fences and pergola posts can look great for 7-10 years with proper maintenance, while deck floors need attention every 2-3 years. Adjust your expectations and maintenance schedule accordingly.

What to Look for in Quality Stain

A good exterior stain should contain:

- Plenty of pigment for UV protection

- Mildewcide to prevent black spots and organic growth

- Fungicide to combat rot

- Oil base for superior penetration and durability (in most applications)

Don’t cheap out on stain. The labor of application—your time or money paid to someone else—will far exceed the material cost. Saving $50 on a gallon of inferior stain is false economy when you have to redo the entire project in two years instead of five.

The Bottom Line

The difference between a structure that looks tired after three years and one that looks beautiful after a decade isn’t the stain brand. It’s understanding that you’re working with a once-living organism that still behaves like a plant. It’s respecting the preparation process. It’s sealing those end cuts. It’s removing the mill glaze. It’s waiting for the wood to dry. It’s choosing an overcast day for application.

These aren’t sexy details. They don’t make for good marketing copy. But they’re what separates the garden structures we’re still maintaining happily after 20 years from the ones we get called to replace after five.

The wood will tell you what it needs—you just have to learn its language.

This article represents decades of hands-on experience building and maintaining outdoor structures in harsh Canadian climate conditions. For specific product recommendations for your climate and wood species, consult with local professionals familiar with your regional conditions.